- Plate Rolls

- HR-4 Series

Control Unit Options For Your Needs

Standard Equipment

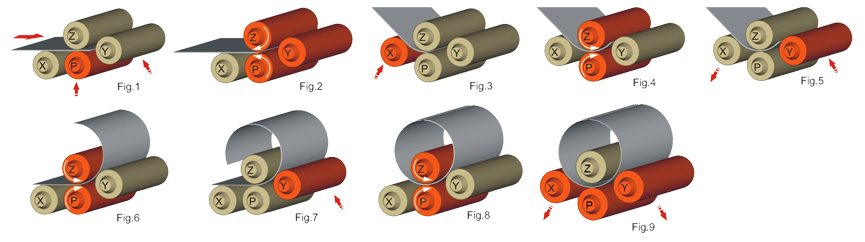

• Planetary type side roll movement.

• PLC Electronic balancing system

• Cone bending • Induction hardened rolls (HRc 56±4)

• Polished rolls • Single speed control of all axis

• Dual speed control of all axis (Standard on NC machines)

• Variable speed control of all axis (Standard on CNC machines)

• Machine body constructed of stress-relieved

• Highly durable carbon steel rolls machined by CNC Lathes with optimal crown (special crown upon request)

• Rolls seated in spherical bearings and bronze bushings

• Hydraulic bracket (drop end) with easy pull out system

• Top and bottom rolls driven with hydraulic motor and planetary gear box

• Automatic rolls peripheral speed compensation

(optimum distribution of torque)

• Adjustable hydraulic pressure on bottom roll (crowning compensation)

• Emergency stop wire around the machine

• Electrical and hydraulic protection against overloads

• World standard electrical and hydraulic components

• Mobile control panel

• Manual lubrication

• Welding possibility on the machine

Optional Features

• NC Control Unit (Simple CNC)

• CNC Control Unit with material database

• AISI 4140 High strength alloy steel rolls

• Four rolls drive

• Wired or wireless remote control

• Oil cooler

• Oil heater

• Side support system (both sides)

• Vertical hydraulic overhead support system

2, 4, 6, 8 or 15 TON (3m - 4m - 5m - 6m diameters)

• Preparation for side or vertical support system

• NC inclusion for vertical support control (Available on CNC control)

• NC inclusion for side support control (Available on CNC control)

• Plate alignment unit

• Automation system

• Changeable top roll for smaller diameter

• Special roll crowning

• Special plate support systems

• Automatic central lubrication

• Material feeding table (Idle or motorized)