- Plate Rolls

- NC Control

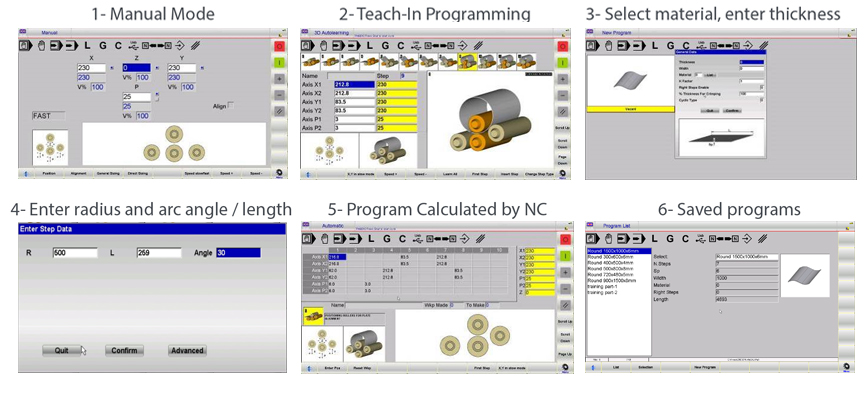

NC control system, in addition to the PLC control system, has the property to work manual, teach-in and automatic modes of operation. In manual mode, the use of all functions are provided by the operator. In teaching mode for the operator to twist all the steps are recorded respectively. In automatic mode all recorded movements are repeated, respectively by the machine. Thanks to the software we developed, the NC unit also calculates the theoretical bending steps one by one. The operator can achieve perfect bend only by changing the pre-bend and rolling values that calculated by the software. NC control system has the capacity to save 2500 programs consisting of Max 100-steps.

Features

NC Control Unit S630

Resistive type 10,1" Touch color screen

Geometric calculations for each bending steps

Hardware

PLC Esautomotion (Made in Italy)

VIA Eden® X1 1.06GHz Memory

1GByte DRAM for CPU

128MByte Solid State Disk

Display Color TFT-LCD 10,1” WVGA (16:9) Resolution (1024 x 600, (R.G.B) )

Integrated VIA Chrome®9 HD DX9 Graphic Cont. Communication ports 1 Ethernet Port 1 CAN interface 1 RS232C Serial Port 2 USB Port,

1 VGA Out

Temprature +5 / 50°C

Software

Manual, teach-in and automatic working modes,

Standard 7 axes (X1,X2,Y1,Y2,P1,P2,Z),

Conic and parallelism control

Dual speed,

200 step, 5000 program memory,

User friendly program editor,

USB port for programs backup ,

Parts quantity programing,

Working hours counter,

mm / inch system,

Automatic turn off programing,

Turkish, English, German, French, Spanish, Portuguese, İtalian, Russian, Polish, Czech, Slovak languages.

Alarm list.