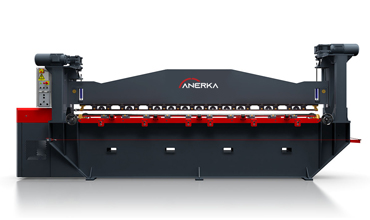

- Superior quality plate & angle roll bending machines

- info@anerka.com

-

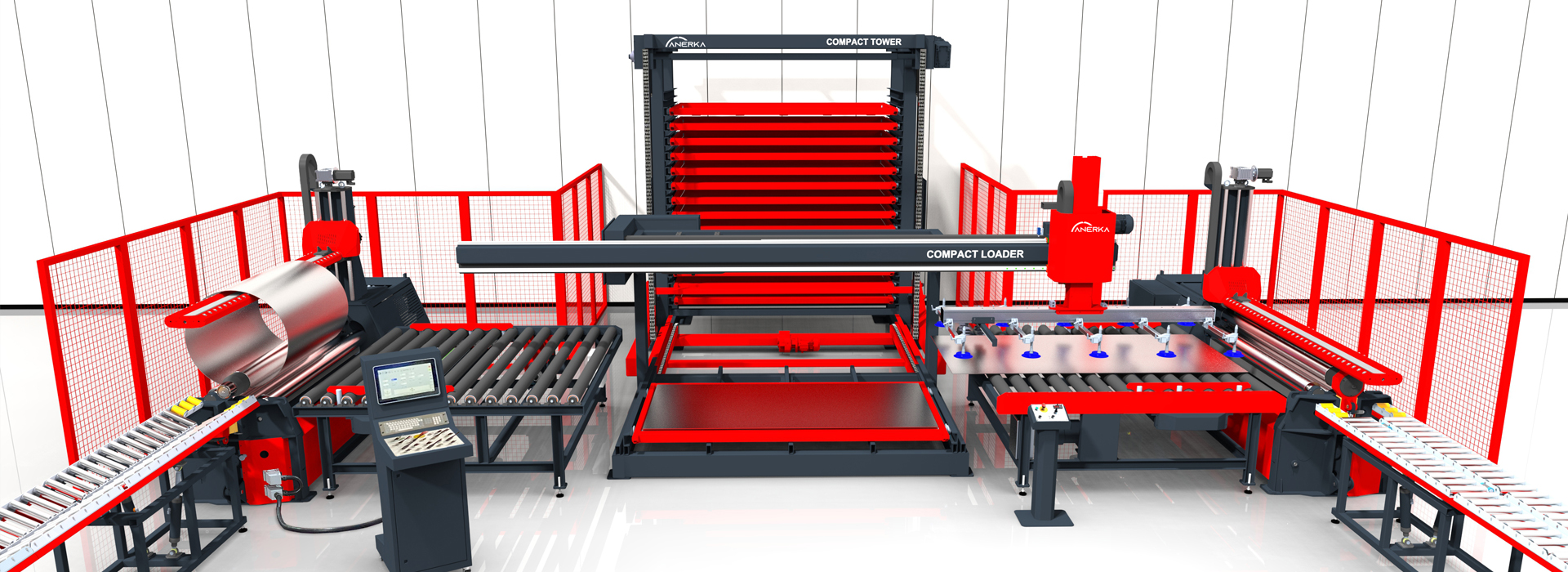

Fully Automated Roll Bending Solutions

Designed for extreme production capacity up to 350,000 parts / year -

Automated Sheet Metal Storage Systems

From tower storage to fully automatic in-line roll bending systems -

Plate Rolls

Wide range production capacity

1mm to 100mm rolling capacity;

0.5m to 8m rolls length -

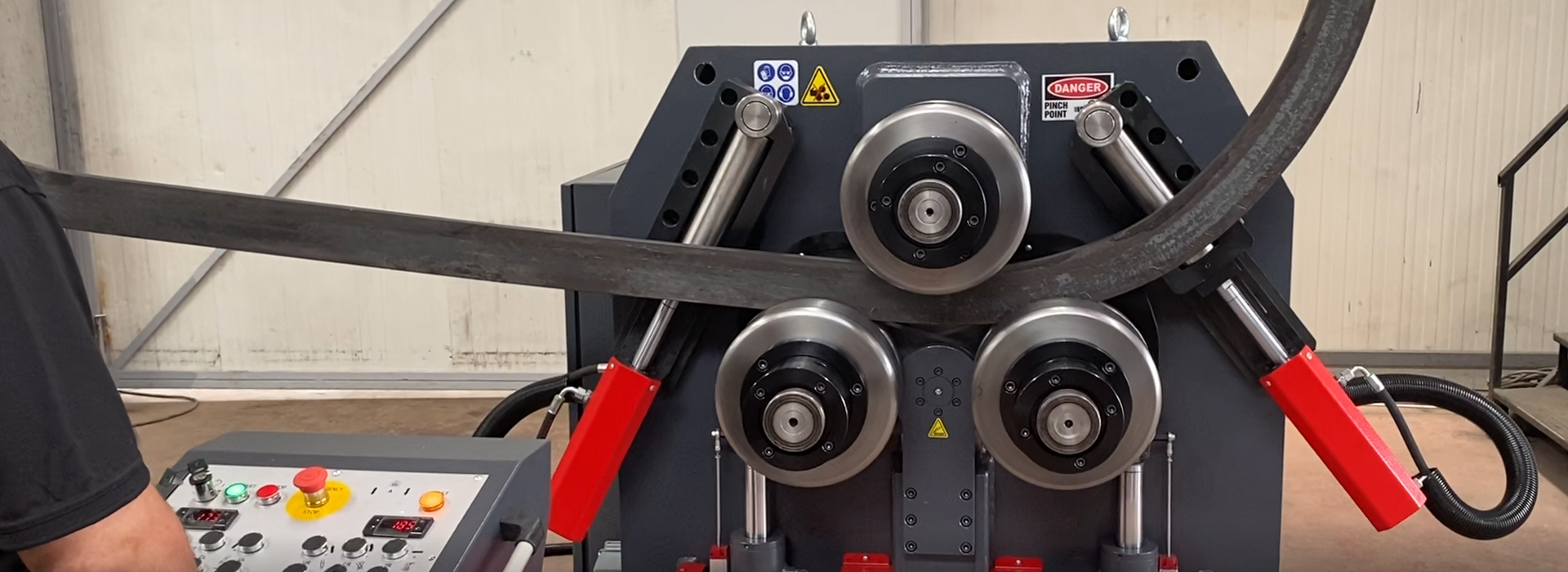

Angle Rolls

Committed to Superior

Committed to Superior

Quality and Results We have a solutionWith many solutions available,

We have a solutionWith many solutions available,

we can configure any machine to exactly match your requirements.Plate Rolls

Download Brochure

HMR-4 Series 4 Rolls

Rectilinear Type Hydraulic & Motorized Four Roll

Light Gauge Sheets, High Volume

0,65 ~ 2m Bending Lengths

Ø80 ~ Ø130 Top roll diamater

1 ~ 6mm Capacity

HR-4 Series 4 Rolls

Planetary Type Hydraulic Four Roll

Light and Mid Plates, High Volume

1~ 8m Bending Lengths

Ø140 ~ Ø430 Top roll diamater

2 ~ 50mm Capacity

HRR-4 Series 4 Rolls

Rectilinear Type Hydraulic Four Roll

Mid and Heavy Plates, High Volume

1 ~ 8m Bending Lengths

Ø330~ Ø760 Top roll diamater

8 ~ 100mm Capacity

HR-3 Series 3 Rolls

Planetary Type Hydraulic Three Roll

Versatile, Mid Plates, Job Shops

1~ 8m Bending Lengths

Ø200 ~ Ø430 Top roll diamater

4 ~ 50mm Capacity

VR-3 Series 3 Rolls

Variable Geometry Hydraulic Three Roll

Mid and Heavy Plates, Rolling Shops

1~ 8m Bending Lengths

Ø350 ~ Ø760 Top roll diamater

10 ~ 100mm Capacity

VMR Series 3 Rolls

Variable Geometry Motorized Three Roll

Light Sheets, Multi Radius Forms

2m ~ 12m Bending Lengths

25mm ~ 50mm Top roll diamater

1 ~ 5mm Capacity

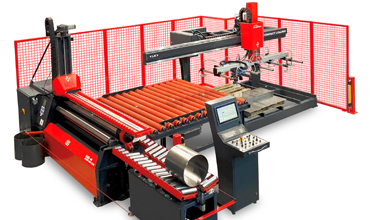

Automation Systems

Fully automated, Loading, Feeding, Squaring, Rolling, Unloading, Transferring, Welding

Light Sheets, Extreme Volumes

1m ~ 3m Bending Lengths

Up to 350,000 parts / year

1 ~ 10mm Capacity

Angle Rolls

Download Brochure

HAR-85 Hydraulic Angle Rolls

Ø85 mm shaft diamaters

30 cm³ Section Modulus Capacity

Up to 3” SCH 40 (Ø89mm) Pipe Bending Capacity

Up to 80mm Angle Bending Capacity

7,5 Kw Main Motor Power

HAR-110 Hydraulic Angle Rolls

Ø110 mm shaft diamaters

60 cm³ Section Modulus Capacity

Up to 4” SCH 40 (Ø114mm) Pipe Bending Capacity

Up to 100mm Angle Bending Capacity

11 Kw Main Motor Power

HAR-140 Hydraulic Angle Rolls

Ø140 mm shaft diamaters

100 cm³ Section Modulus Capacity

Up to 5” SCH 40 (Ø141mm) Pipe Bending Capacity

Up to 120mm Angle Bending Capacity

15 Kw Main Motor Power

HAR-190 Hydraulic Angle Rolls

Ø190/170 mm shaft diamaters

220 cm³ Section Modulus Capacity

Up to 6” SCH 40 (Ø168mm) Pipe Bending Capacity

Up to 120mm Angle Bending Capacity

22 Kw Main Motor Power

HAR-240 Hydraulic Angle Rolls

Ø240/220 mm shaft diamaters

600 cm³ Section Modulus Capacity

Up to 8” SCH 40 (Ø219mm) Pipe Bending Capacity

Up to 160mm Angle Bending Capacity

37 Kw Main Motor Power

HAR-300 Hydraulic Angle Rolls

Ø300/280 mm shaft diamaters

1600 cm³ Section Modulus Capacity

Up to 12” SCH 40 (Ø324mm) Pipe Bending Capacity

Up to 200mm Angle Bending Capacity

45+15 Kw Main Motor Power

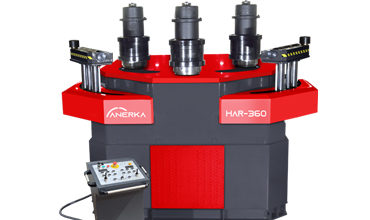

HAR-360 Hydraulic Angle Rolls

Ø360/340 mm shaft diamaters

6500 cm³ Section Modulus Capacity

Up to 20” SCH 40 (Ø508mm) Pipe Bending Capacity

Up to 200mm Angle Bending Capacity

55+22 Kw Main Motor Power

Advantages of Anerka Plate & Angle Rolls

• Quality begins on the inside and at Anerka our machines are loaded with top-of-the-line world class components. Duplomatic valves, Marzocchi pumps, Bonfiglioli gearboxes, Siemens electrical components, Opkon encoders.

• Stress-relieved box design frames and chassis. This helps increase stiffness and reduce flexing of the machine, insuring optimal bending results.

• Largest roll shaft diameter of any comparably sized machine. This helps minimize shaft deflection even under maximum load, allowing you to produce better roll results.

• Highest drive torque per machine per size.

• Most powerful bending forces generated by the two lower (side) rolls. Together with the highest drive torque, productivity is increased, your rolling jobs are completed faster.

• Only SKF / FAG bearings used throughout the machine.

• High strength forged and quenched CK45 & 4140 steel used for all roll tooling.

About Anerka

Anerka was established in Bursa / Turkey in 2016 by Atakan Nerminer and Ramazan Kaba who has more than 25 years of experience in the design and production of roll bending and profile bending machines.

Mission Statement

Anerka is committed: To provide the highest quality product possible through our highly skilled and dedicated employees and state-of-the-art and patented products and manufacturing process. To pursue an aggressive, outgoing research and development program thus insuring its future as a leader in sheet metal working machines. To provide the highest standards of service available through our highly trained, domestic and international field representatives and customer service personnel. Propper employees are expected to serve the customer with the highest level of technical knowledge in the industry.FAQ

Why Should I Consider a 4 Rolls Over a 3 Rolls?

With our 4 roll machines the bottom roll moves up to pinch the plate edge securely against the top roll while the side roll is raised to form an accurate pre-bend, minimizing the flat zone on the plate edge. Pre-bending on a three roll machine requires that plates be tilted down as they are being fed. In contrast, plates are loaded horizontally at the feed level for pre-bending on our four roll machine, which allows the use of horizontal motorized roller tables to help feed the plate. Plate feeding can take place on either side of our four roll machine. If fed from only one side, they can even be placed up against a wall to save floor space. The side rolls are positioned to the right and left of the bottom roll and are on their own axes. The independent axis of each roll helps make a perfect bend. The “back” side roll (at the far side of the feeding point) also functions as a back gauge to square the plate for proper alignment. This eliminates the need for someone to assist the operator. The plate is kept square without slipping during both pre-bending and rolling because of the constant secure clamping of the top and bottom rolls.

What machine is ideal for cone bending?

Cone rolling is easier on a four roll machine. The side rolls can be tilted to establish the cone angle and the bottom roll can also be tilted to clamp and drive the plate. Our HR-4 series plate rolls are designed to utilize planetary guides. Our HRR-4 series plate rolls are controlled by rectilinear guides that provide the controlled movement required to create accurate bends and this design increases the longevity of the machines life. This system allows bending of as small as 1.1 times the diameter of the top roll, providing the tightest bend radius in the industry. Through superior construction and design, a massive heavy weight frames and the ability to angle bottom and side rolls our 4 roll plate roller can bend wide angle and small diameter conical parts with ease, with minimal effort from the operator. While most machines on the market can conically bend three times the diameter of the top roll, ours can conically bend 1.5 times the diameter of the top roll and frequently smaller diameters than that. Roll cones like a seasoned plate roll operator.

What is benefits of 4 Rolls?

• The fastest and most accurate bends are made by four roll machines. The plate is held securely in place between the top and bottom rolls while the side rolls move vertically to create the bend.

• The bottom roll moves up to hold the plate edge securely against the top roll while the side roll is raised to form an accurate pre-bend, minimizing the flat zone on the plate edge. Pre-bending on a double pinch three roll machine requires that plates be tilted down as they are being fed. In contrast, plates are loaded horizontally at the feed level for pre-bending on a four roll machine, which allows the use of horizontal motorized roller tables to help feed the plate.

• Plate feeding can take place on either side of a four roll machine. If fed from only one side, they can even be placed up against a wall to save floor space.

• The side rolls are positioned to the right and left of the bottom roll and are on their own axes. The independent axis of each roll helps make a perfect bend. The “back” side roll (at the far side of the feeding point) also functions as a back gauge to square the plate for proper alignment (see figure 1). This eliminates the need for someone to assist the operator.

• The plate is kept square without slipping during both pre-bending and rolling because of the constant secure clamping of the top and bottom rolls.

• Four roll machines do not require the operator to remove, flip, and then try to square the plate a second time after pre-bending, as is the case with three roll initial pinch (IP) machines. Keeping the material in the machine makes four rolls 50% more efficient than three roll IP machines, and allows a cylinder to be rolled to the required diameter immediately following pre-bending.

• Bending the back edge takes place after the cylinder is rolled, for a one direction, single pass operation.

• Cone rolling is easier on a four roll machine. The side rolls can be tilted to establish the cone angle and the bottom roll can also be tilted to clamp and drive the plate.

• Four roll machines are the only type of plate rolls that can effectively make use of NC and CNC controls because of the constant clamping and driving of the material during all steps of rolling. Bending difficult shapes like polycentric or elliptic work pieces can be easily done with CNC four roll machines. .Upcoming Exhibitions